Qingdao Today

2024/4/29

2024/4/29

source:

source:

Print

Print

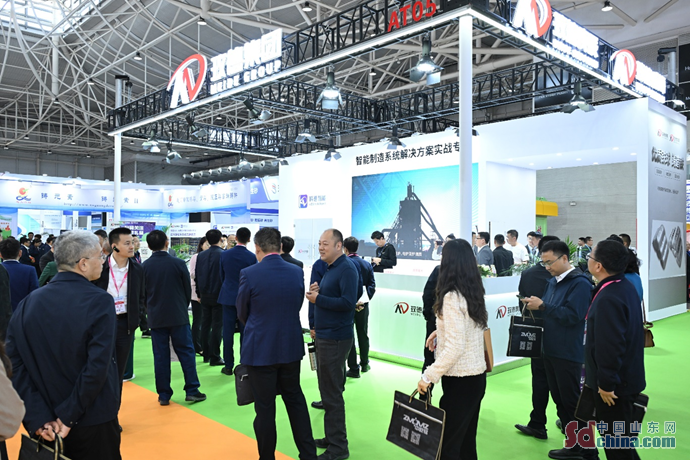

The 6th Shandong International Foundry Industry Exhibition opened at Qingdao Cosmopolitan Exposition Center on April 26, which lasts for three days.

The exhibition centers on the objective of achieving the "dual carbon" goal and consistently showcases a strategic approach that aligns with the pulse of industry development. It advocates for enterprises to adopt an innovative and efficient path towards green development of foundry industry, while efficiently linking the industry chain and cross-domain information and resources. This will help in achieving the goal of "peak carbon dioxide emissions and carbon neutrality".

The exhibition covers an area of 30,000 square meters, attracting 400 domestic enterprises to participate in. Focusing on digitization, intelligence, and greenization, the exhibition highlights various high-quality casting products, as well as related foundry equipment, processes, environmental friendly raw and auxiliary materials, tooling molds, casting quality inspection equipment, intelligent technology, and environmental protection equipment. The entire industrial chain in the exhibition showcases new technologies, processes, and materials, with an overwhelming surge of momentum accelerating the formation of new quality productive forces.

New quality productive force has become a key term of this exhibition. The event not only showcased a variety of high-precision and cutting-edge new technologies and new processes such as intelligent equipment for underground sand processing, intelligent storage for casting, automated production lines for casting shapes, and 3D printing, but also provided strong momentum for the sustainable development of the foundry industry.

During the exhibition, the 2024 Symposium on New Quality Productive Force Development in Foundry Industry was held, focusing on the development of new quality productive force. Discussions and exchanges were conducted on topics such as the transformation and upgrading of the foundry industry, innovative technologies and achievements in intelligent manufacturing. The discussions were insightful and in-depth, providing new concepts, new ideas, and new impetus for the development of new quality productive forces in the foundry industry.